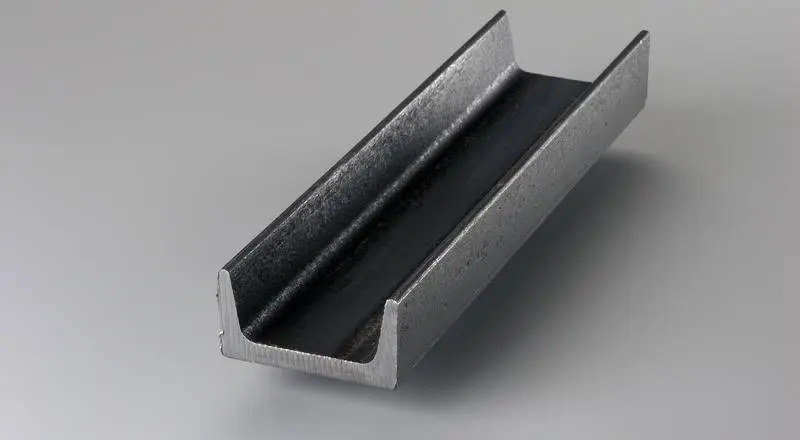

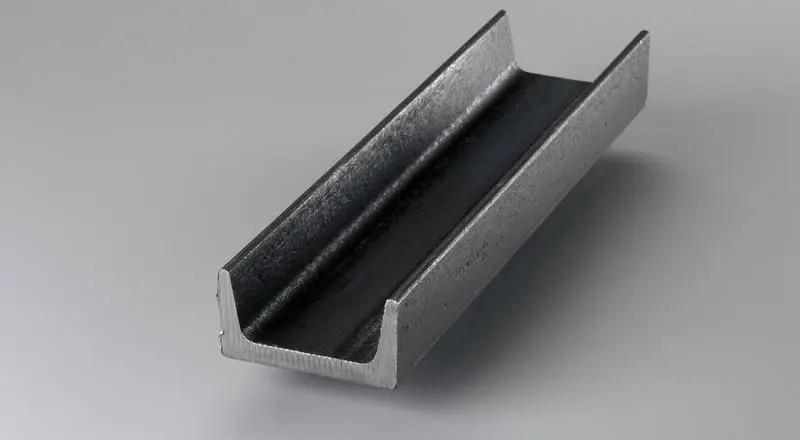

C Channel Steel / Channel Steel / C-Section

C Channel Steel (C-Section / Channel Steel) for structural framing and fabrication—strong, versatile, and easy to weld or bolt. Available in common sizes, thicknesses, and lengths with export-ready packing.

Eastern Steel supplies C Channel Steel / Channel Steel / C-Section used across construction and industrial fabrication for its excellent strength-to-weight ratio and practical “C” profile. C channels are widely applied in steel structures, purlins and framing, equipment supports, platforms, truck bodies and trailers, solar mounting systems, warehouse racking, and general fabrication, where reliable load support and fast installation are required.

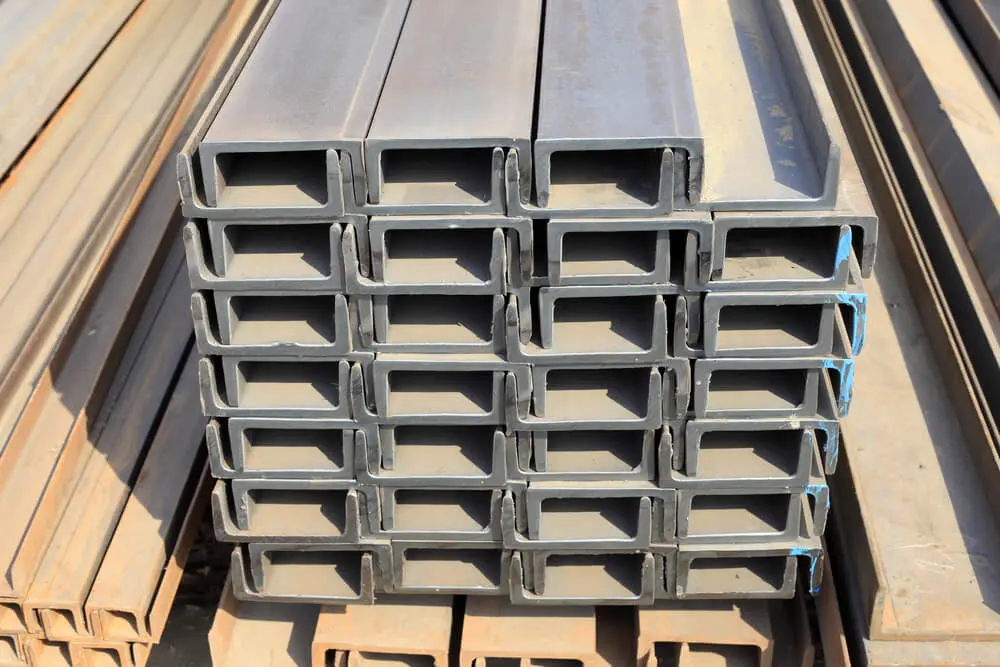

Supply can be arranged in a broad range of section dimensions and thicknesses, with standard lengths and cutting options available to meet project requirements. Eastern Steel supports export buyers with Mill Test Certificates (MTC), optional inspection coordination (SGS/BV), and secure export packing/loading plans suitable for container or breakbulk shipment depending on length and quantity.

| Standards: GB/T 707, EN 10279, ASTM A36 / A572 / A529, JIS G3192 |

| Material Grades: Q235B, Q345B, Q355B, S235JR, S275JR, S355JR, ASTM A36, A572 Gr.50 |

| Height: 40 mm – 300 mm |

| Flange Width (B): 20 mm – 100 mm |

| Web Thickness (t1): 4 mm – 13 mm |

| Flange Thickness (t2): 4 mm – 14 mm |

| Weight: 2.5 kg/m – 40 kg/m |

| Length: 6 m, 9 m, 12 m (custom lengths available) |

| Surface Treatments: Black Hot-Rolled, Electro-Galvanized, Hot-Dip Galvanized, Painted/Primer Coated |

| Yield Strength: 235–355 MPa (depending on grade) |

| Tensile Strength: 370–630 MPa (depending on grade) |

| Elongation: 18–25% |

| Manufacturing Type: Hot Rolled / Cold Formed |

| Applications: Steel structures, frames, machinery, vehicle chassis, warehouse racking, support beams, fabrication works |