Seamless Steel Pipe

Seamless Steel Pipe for high-pressure and high-temperature service in oil & gas, boilers, mechanical engineering, and construction. Supplied in multiple grades and dimensions with full documentation and inspection support.

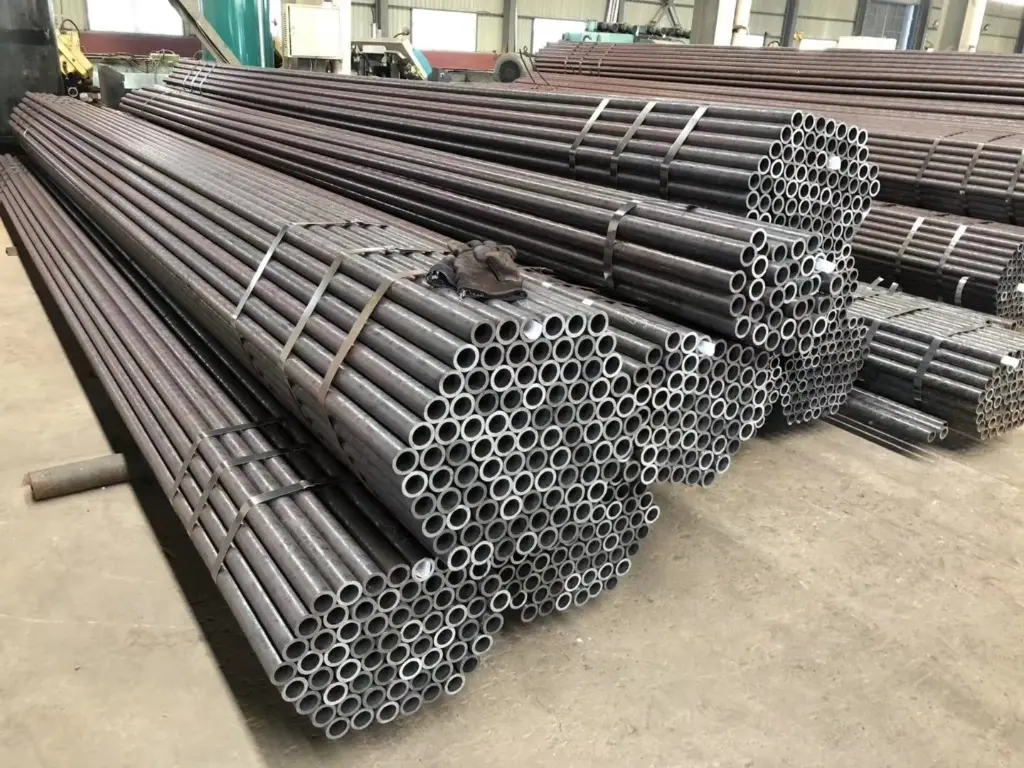

Eastern Steel supplies Seamless Steel Pipe manufactured without a welded seam, offering reliable strength, uniform structure, and excellent performance under pressure and temperature extremes. Seamless pipes are widely specified for oil & gas transmission, boiler and heat exchanger systems, petrochemical plants, power generation, hydraulic systems, mechanical tubing, and structural applications where consistent integrity is critical.

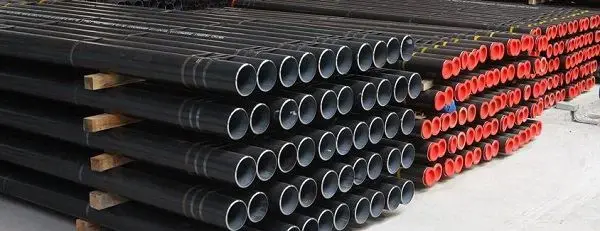

We can support common international standards and grades depending on your application, with supply options typically covering a broad range of outer diameters, wall thicknesses, lengths, end types (plain/beveled/threaded), and heat treatment conditions. Eastern Steel supports export buyers with Mill Test Certificates (MTC), heat/lot traceability, inspection coordination (SGS/BV on request), and export-ready packing, including bundle packing, end protectors, and container loading plans.

| Outer Diameter (OD): 10–610 mm (Hot Rolled), 6–219 mm (Cold Drawn) |

| Wall Thickness: 1.5–60 mm |

| Length: 5.8 m / 6 m / 11.8 m / 12 m (fixed or random) |

| Steel Grades (Carbon Steel): ASTM A106 Gr.A/B/C; ASTM A53 Gr.A/B; API 5L Gr.B/X42/X52/X60/X65; S235/S275/S355; 20#, Q345B/Q355B |

| Boiler/High-Pressure Grades: 20G, 15CrMoG, 12Cr1MoVG, ST45.8, T11, T22 |

| Structural Grades: GB/T 8162 grades: 10#, 20#, 35#, 45# |

| Manufacturing Process: Hot Rolled, Cold Drawn (CD), Cold Rolled (CR) |

| Surface Treatment: Black, Oiled, Varnish, Anti-rust Oil, FBE/3PE Coated (optional) |

| End Types: Plain End (PE), Beveled End (BE), Threaded with Coupling |

| Tolerances: OD ±0.5–1%, WT ±10%, Length +10 / –0 mm |

| Standards: ASTM, API, EN, DIN, JIS, GB/T |

| Applications: Oil & gas pipelines, mechanical parts, automotive, boilers, hydraulic systems, construction |